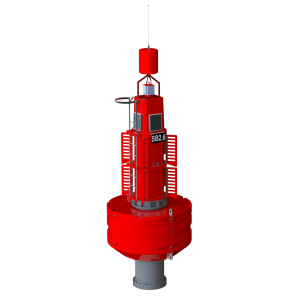

SB-138P

SENTINEL® BUOY

The SB-138P Sentinel® buoy is a product of Tideland Signal’s continued commitment in developing new higher performance, low maintenance, cost effective marine aids to navigation. Deployed in over 40 countries, the SB- 138P buoy utilises the benefits of the latest in materials, manufacturing processes and technology. Providing a rugged, lightweight buoy with exceptional station-keeping and long life, while reducing the long term maintenance expense typically associated with floating aids to navigation.

FEATURES

- UV-STABILISED POLYETHYLENE – Rotationally moulded to form a seamless body, 9.5mm thick. Through a unique mould design and a controlled process, an increased thickness is formed at major stress points.

- DIVIDED INTO THREE SECTIONS – A float section, battery section and a nav-aid section form an abrasion resistant, shock absorbing buoy able to withstand knocks and/or collisions. The float section has a moulded in slip resistant surface, providing an added safety precaution for on station maintenance.

- MATCHING OR ALTERNATING SECTIONS – Easily makes bifurcation buoys, either red or green as required. Cardinal boys can be assembled using the same method, with yellow and black sections. Fairway or Safe Water buoys are produced using a process of moulded in colour graphics, resulting in red and white vertical striping.

- LONG-TERM STRENGTH AND SECURITY – The float section is internally cross-braced with stainless steel rods that are connected to stainless steel bushings in

- mooring and lifting eyes. Mooring eyes are fitted with a replaceable stainless steel wear bushing.

- STABILITY – Achieved by filling float section with a calculated amount of reinforced concrete as ballast. Then the entire float section is filled with polystyrene beads.

- The float is then sealed and placed into a steam-chest to expand the foam beads to maximum size, fusing the beads together. This process results in one solid piece of polystyrene completely filling all voids, preventing water ingress in the event of puncture, adding ruggedness to an

- already tough floating aid.

POWER

- Configured for 12V or 24V nominal, the power system for the lantern and optional equipment is housed in the battery section, which also forms part of the tower for the lantern.

NAVAID SECTION

- Has provision for four 10 peak watt solar modules or up to three 20 peak and one ten peak watt solar modules.

- Configurations of solar modules can vary depending on electrical load and average insolation for area of deployment. This section also includes

- an internal high gain passive reflector (10m2) and lantern guard (if needed). Access to battery section and all equipment is through a hinged, tamper resistant, watertight service hatch, located in the navaid section.